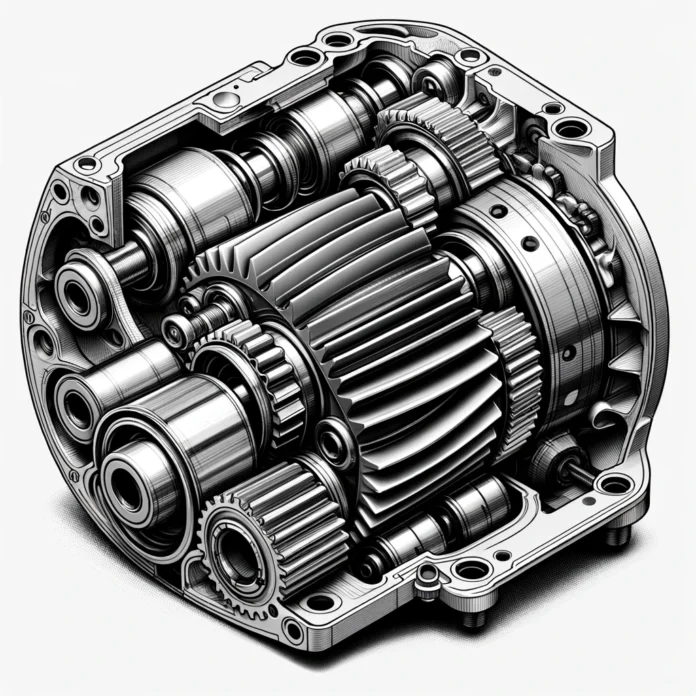

Welcome to the fascinating world of precision engineering – where every turn and twist matters in the grand dance of machinery. At the heart of this world lies a marvel of mechanical ingenuity: the cycloidal gearbox. Whether you’re a seasoned engineer or a curious enthusiast, the intricacies of cycloidal gearboxes. Prepare to delve into the mechanical poetry that keeps our robots moving and our industries churning.

Understanding the Basics: What is a Cycloidal Gearbox?

Before we leap into the complexities, let’s establish what a cycloidal gearbox is. Imagine a system designed for maximum efficiency and durability, capable of handling high loads gracefully. This is the cycloidal gearbox, the unsung hero in motion control, where precision meets reliability.

The Design Marvel: How a Cycloidal Gearbox Works

The Cycloidal Disc: The Heartbeat of the System

At the centre of a cycloidal gearbox’s operation is the cycloidal disc. Picture a disc that does not rotate in a typical circular fashion but in a cycloidal path. This path ensures that the load is distributed evenly across multiple gear teeth, reducing wear and extending the life of the machinery.

Eccentric Motion: The Power Behind the Precision

An eccentric cam provides the heartbeat for the cycloidal disc, converting rotational motion into controlled cycloidal movement. This conversion is a symphony of mechanical harmony, resulting in a high torque output from a compact design.

The Unsung Benefits: Why Choose a Cycloidal Gearbox?

High Load Capacity: The Bearer of Burdens

Cycloidal gearboxes are the strongmen of the gear world, capable of handling loads that would make other gears falter. Their robust design distributes stresses in a way that allows for smooth operation under the pressure of high-torque applications.

Precision and Backlash: The Twin Pillars of Control

In motion control, precision is paramount. The cycloidal gearbox boasts near-zero backlash, a critical feature for applications requiring the utmost accuracy, such as robotics and automation.

From Theory to Practice: Cycloidal Gearboxes in the Real World

Robotics: The Articulate Limbs of Automation

In robotics, cycloidal gearboxes are the joints that offer precise and fluid movement. From industrial arms to humanoid robots, they ensure smooth and accurate movements.

Industrial Applications: The Workhorses of Production

Beyond robotics, these gearboxes are the driving force behind countless industrial applications. They ensure that from packaging to processing, production lines operate like clockwork.

A Peek into the Future: Innovations and Advancements

As technology gallops forward, cycloidal gearboxes are still being included. Innovations in materials and design continue to push their capabilities, opening new frontiers in efficiency and performance.

The Verdict: Why Cycloidal Gearboxes are Here to Stay

Durable, efficient, and precise – the cycloidal gearbox may not be a household name, but it’s a cornerstone of modern machinery. In a world that demands more, these gearboxes deliver performance that’s hard to match.

Cycloidal Gearbox Formula: The Mathematics of Movement

The cycloidal gearbox operates on complex mathematics, but don’t let that intimidate you. At its core, the formula involves understanding the cycloidal path – a geometric curve traced by a point on the circumference of a circle rolling along a straight line. Engineers use this principle to calculate the precise dimensions and movements required for the gearbox to function efficiently and with low backlash. Essential variables in the formula include:

- The size of the cycloidal disc.

- The number of lobes.

- The eccentricity of the cam.

Cycloidal Gearbox Manufacturers: Crafting Precision

When it comes to producing cycloidal gearboxes, there’s a blend of time-honoured craftsmanship and cutting-edge technology. Several leading manufacturers stand out in the industry, renowned for their commitment to quality and innovation. Companies like Nabtesco, Sumitomo, and Onvio have set high standards with their robust designs and meticulous manufacturing processes. These industry giants produce gearboxes and drive technological advancements in the field.

Cycloidal Gearbox Price: Investing in Quality

Discussing price can be tricky as it ranges widely based on size, customization, and additional features. However, investing in a high-quality cycloidal gearbox translates to cost savings in the long run due to its durability and low maintenance requirements. When considering the price, factor in the gearbox’s longevity and ability to reduce downtime in critical applications.

Cycloidal Gearbox vs Cycloid: Understanding the Distinction

While the terms are often used interchangeably, there is a subtle distinction between a ‘cycloidal gearbox’ and a ‘cycloid’. The former refers to the entire mechanical assembly, while the latter typically describes the path or curve the gears follow. Understanding this difference is crucial for professionals and enthusiasts alike when discussing or researching these components.

Cycloidal Gearbox Catalogue: A Repository of Specifications

A cycloidal gearbox catalogue is an essential resource for engineers and buyers, providing detailed specifications, dimensions, and options. It guides the different models available and helps select the right gearbox for specific applications. These catalogues are often available on manufacturers’ websites and are a valuable tool for comparison and selection.

Cycloidal Gearbox Design: The Blueprint of Efficiency

Designing a cycloidal gearbox requires a deep understanding of mechanical principles and focusing on the end-use application. The design process involves:

- Choosing the suitable materials.

- Determining the number of lobes on the cycloidal disc.

- Ensuring the gearbox can withstand the required torque and load.

The end goal is to achieve a balance between size, efficiency, and durability.

Cycloidal Gearbox Ratio: The Ratio of Rotation

The gearbox ratio is a critical factor in the design and function of a cycloidal gearbox. It determines how the input speed is reduced, and torque is increased to meet the needs of various applications. A well-calculated gearbox ratio ensures optimal performance, allowing for precise control of machinery and equipment.

Cycloidal Gearbox Applications: Where Precision Meets Practice

The versatility of cycloidal gearboxes means they’re found in many applications, from robotics to aerospace. Their ability to handle high loads with precision makes them ideal for industrial robots, machine tools, and positioning systems. Each application benefits from the gearbox’s unique advantages, including its compact design, high ratio, and low backlash.